You’ll maximize industrial maintenance efficiency by leveraging real-time data visualization overlays that provide instant equipment insights, implementing remote expert assistance through AR headsets for complex repairs, and using virtual prototyping to test procedures safely. Integrate digital twin technology with mixed reality systems, deploy hands-free training simulations for hazardous scenarios, optimize safety protocols with visual hazard detection, and combine predictive analytics with augmented workflows. These strategies can reduce maintenance costs by 30% while transforming your entire operational approach.

Leverage Real-Time Data Visualization for Equipment Monitoring

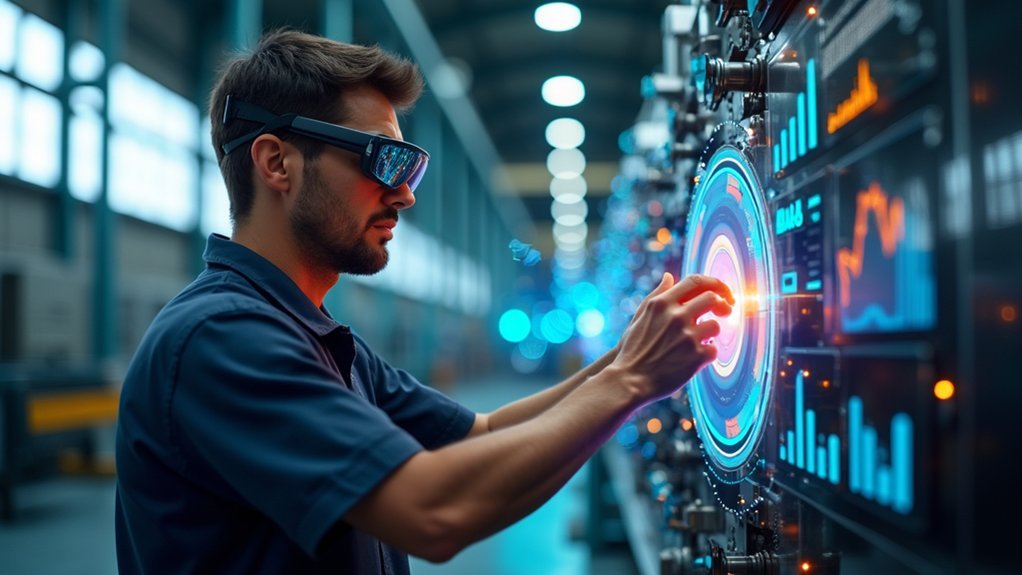

Precision becomes paramount when monitoring complex industrial equipment, and real-time data visualization in mixed reality transforms how you access critical performance information.

You’ll overlay contextual metrics directly onto machinery, enabling instant anomaly detection during maintenance tasks. GE’s turbine monitoring system exemplifies this approach, allowing engineers to make rapid decisions based on live visual feedback.

AR solutions like Bosch’s troubleshooting platforms merge real-time data with physical environments, simplifying complex machinery diagnostics.

AR platforms seamlessly integrate live performance data with physical machinery, revolutionizing how technicians diagnose and resolve complex industrial equipment issues.

You’ll understand equipment interactions faster, leading to quicker issue resolution in industrial operations. This immediate access to critical information guarantees informed decision-making while performing repairs.

Implementing these visualization tools delivers efficiency and reduced downtime, greatly cutting maintenance costs by equipping you with instant access to performance metrics when you need them most.

Implement Remote Expert Assistance Through Mixed Reality Platforms

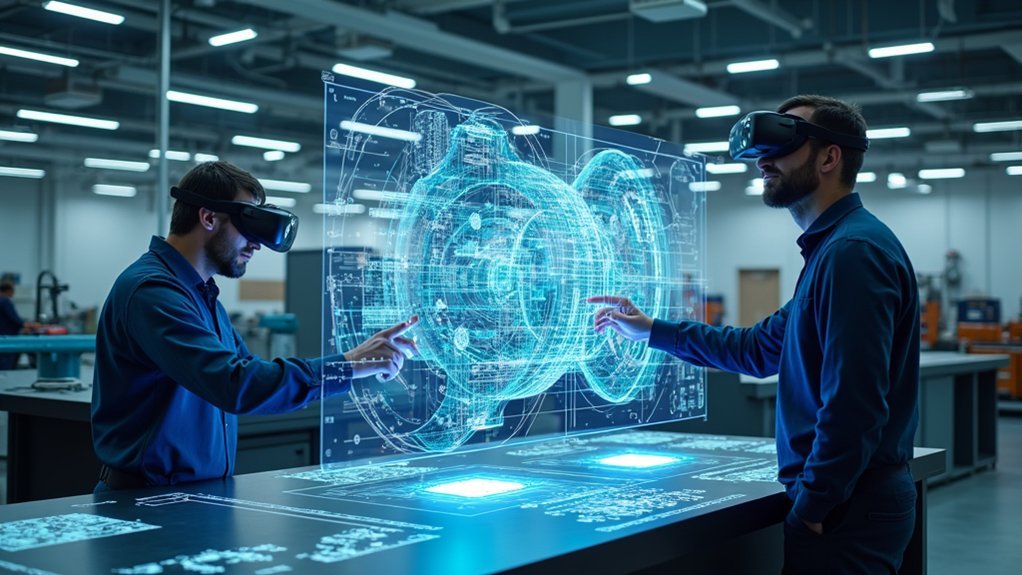

When on-site technicians encounter complex maintenance challenges beyond their expertise, mixed reality platforms bridge the knowledge gap by connecting them instantly with remote specialists.

This remote assistance technology transforms how you approach technical support by enabling experts to see exactly what you’re seeing through augmented reality (AR) headsets.

You’ll receive real-time guidance as specialists overlay critical information directly onto your field of view, dramatically improving first-time fix rates.

Multiple experts can collaborate simultaneously from different locations, eliminating costly travel while maintaining service quality.

Consider these operational improvements:

- Reduced repair times through immediate expert consultation and visual instruction overlays

- Lower travel costs by enabling remote collaboration instead of on-site specialist visits

- Enhanced comprehension with AR-based step-by-step guidance for complex maintenance procedures

Use Virtual Prototyping to Test Maintenance Procedures Before Deployment

You can simulate complex repair tasks through virtual prototyping to test maintenance procedures without putting physical equipment at risk.

This approach lets you optimize the sequence of procedure steps by running multiple scenarios and identifying the most efficient workflow.

You’ll discover potential issues and refine your maintenance protocols before deploying them in real-world environments.

Simulate Complex Repair Tasks

Although traditional maintenance training relies on physical equipment and real-world scenarios, virtual prototyping transforms how you’ll prepare for complex repair tasks.

AR technology creates immersive experiences that let technicians practice intricate procedures without risking expensive equipment damage or downtime.

You’ll discover that virtual prototyping enables sophisticated simulation of challenging maintenance scenarios.

Here’s how you can maximize these capabilities:

- Practice high-risk procedures safely – Simulate dangerous repairs without exposing technicians to actual hazards

- Refine repair strategies iteratively – Test multiple approaches to complex repairs before implementation

- Enhance predictive maintenance skills – Train technicians to identify potential failures through realistic 3D visualizations

This approach dramatically improves your team’s readiness while reducing costs associated with physical training equipment and potential mistakes during actual repairs.

Reduce Physical Equipment Risk

Since physical equipment failures can cost thousands in downtime and repairs, virtual prototyping offers a strategic solution that eliminates these risks entirely. You’ll test maintenance procedures through AR before deployment, allowing technicians to practice complex tasks without touching actual machinery. This immersive approach helps you identify potential issues early while establishing robust safety protocols.

| Traditional Approach | Virtual Prototyping Benefits |

|---|---|

| Physical equipment exposure | Risk-free testing environment |

| Costly trial-and-error | Quick design iterations |

| Limited practice scenarios | Multiple maintenance simulations |

| Potential safety hazards | Enhanced technician training |

| Operational disruptions | Reducing downtime considerably |

You’ll find that virtual prototyping transforms how your team approaches maintenance planning, creating safer work environments while improving operational efficiency through thorough pre-deployment testing.

Optimize Procedure Step Sequences

When maintenance procedures involve multiple interdependent steps, virtual prototyping becomes your most powerful tool for sequence enhancement.

You’ll discover critical bottlenecks and inefficiencies before they impact real operations. Mixed reality environments let you test and refine maintenance workflows, ensuring technicians follow the most effective sequences when deployed.

You can leverage augmented reality (AR) to:

- Simulate complex procedures – Test intricate maintenance tasks virtually to identify ideal step arrangements and eliminate potential errors.

- Standardize workflows – Create consistent, validated procedures that enhance quality across all maintenance operations.

- Accelerate training – Prepare technicians with pre-tested sequences, reducing actual repair time and boosting confidence.

Companies like Ford have proven this approach dramatically improves operational efficiency while minimizing costly mistakes during actual maintenance deployment.

Integrate Digital Twin Technology With Mixed Reality Systems

You can transform your maintenance operations by connecting digital twin technology with mixed reality systems to create powerful real-time process visualization capabilities.

This integration lets you overlay live operational data directly onto physical equipment, giving you immediate insights into performance metrics and system conditions.

You’ll optimize predictive maintenance strategies by analyzing integrated data streams that help you anticipate equipment failures before they occur.

Real-Time Process Visualization

While traditional maintenance approaches rely on static data and periodic inspections, integrating digital twin technology with mixed reality systems transforms how you monitor and interact with industrial equipment.

Real-time visualization enables you to see exactly what’s happening inside your machinery without physical disassembly, making industrial maintenance more efficient and accurate.

Mixed reality overlays digital representations directly onto physical equipment, giving you immediate access to performance data, temperature readings, and operational status.

This technology revolutionizes your approach through:

- Enhanced predictive maintenance – You’ll identify potential failures before they occur by visualizing real-time equipment conditions

- Improved training programs – New technicians learn faster through immersive, hands-on experiences with digital twins

- Optimized decision-making – You can test scenarios and modifications virtually before implementing changes

Predictive Maintenance Optimization

Although traditional maintenance schedules often follow rigid timelines regardless of actual equipment condition, digital twin technology combined with mixed reality systems enables you to shift toward truly predictive maintenance strategies. This integration provides real-time simulation capabilities that’ll transform how you monitor equipment performance and predict failures.

| Traditional Approach | Digital Twin + Mixed Reality |

|---|---|

| Fixed maintenance schedules | Dynamic, condition-based maintenance |

| Reactive problem solving | Proactive interventions before failures |

| Limited equipment visibility | Real-time simulation overlays |

| Higher downtime costs | Reduced operational disruptions |

| Manual data interpretation | Interactive predictive analytics |

You’ll visualize digital twin status alongside physical components, enabling quicker issue identification. This enhanced decision-making reduces downtime while extending machinery lifespan. Companies report decreased maintenance costs and improved operational efficiency through accurate resource allocation and optimized task prioritization.

Operational Data Integration

When operational data flows seamlessly between digital twins and mixed reality systems, you’ll gain unprecedented insight into your equipment’s real-time performance.

This integration transforms how you approach industrial maintenance by combining augmented reality (AR) with digital twin technology to create powerful visualization capabilities.

Here’s how to maximize operational data integration:

- Connect IoT sensors directly to your digital twins – Stream live performance metrics into your mixed reality interface for instant access to critical operational data during maintenance tasks.

- Implement real-time visualization dashboards – Overlay equipment status, temperature readings, and performance indicators onto physical machinery using AR displays.

- Create immersive environments for predictive maintenance – Use integrated data to identify potential failures before they occur, enabling proactive maintenance scheduling and reducing costly downtime.

Deploy Hands-Free Training Simulations for Complex Repair Tasks

Since complex repair tasks demand both mental focus and physical dexterity, hands-free training simulations in mixed reality offer an ideal solution for industrial maintenance education. You’ll experience AR overlays that provide real-time guidance directly on equipment, eliminating manual reference materials while keeping your hands free for actual work.

These mixed reality simulations replicate hazardous scenarios safely, allowing you to practice complex repair tasks without risk. You’ll develop technician confidence through immersive experiences that enhance skill retention and performance.

| Training Benefit | Impact |

|---|---|

| Productivity Timeline | 30% faster competency |

| Safety Training | Risk-free hazardous scenarios |

| Learning Retention | Enhanced skill memory |

| Reference Materials | Eliminated physical manuals |

| Real-World Application | Improved actual performance |

This hands-free approach transforms how you’ll master industrial maintenance skills efficiently.

Optimize Safety Protocols With Visual Hazard Detection Overlays

While traditional safety protocols rely on manual inspections and static checklists, mixed reality transforms hazard detection by overlaying real-time visual alerts directly into your field of view.

Mixed reality eliminates the dangerous disconnect between safety information and active work by delivering critical alerts directly within your visual workspace.

You’ll receive immediate notifications about machinery malfunctions, unsafe environments, and required safety measures without looking away from your work.

This advanced approach to safety protocols greatly reduces workplace accidents by keeping critical information within your technician’s field of view.

Here’s how you can optimize your safety implementation:

- Automated PPE reminders – Visual overlays display required protective equipment before task initiation

- Lockout/tagout procedures – Superimposed step-by-step safety sequences guarantee proper compliance

- Real-time hazard alerts – Instant visual cues identify potential risks and prompt corrective actions

Mixed reality (MR) visual hazard detection creates a proactive safety culture while maintaining operational efficiency.

Combine Predictive Analytics With Augmented Maintenance Workflows

Although traditional maintenance schedules follow rigid timelines, predictive analytics revolutionizes your approach by forecasting equipment failures before they occur.

By integrating predictive analytics with augmented reality (AR), you’ll enhance maintenance workflows through real-time data visualization overlaid directly onto your equipment. This combination empowers technicians to prioritize tasks based on predicted failure likelihood and urgency levels.

You’ll streamline maintenance schedules by performing repairs at ideal times, considerably reducing equipment downtime. AR systems leverage historical maintenance data to suggest best practices tailored to specific machinery.

Your operational efficiency improves as technicians access predictive insights instantly through visual overlays. Additionally, this integration enhances training programs by simulating real-time scenarios with predictive data, helping technicians understand how their actions impact equipment performance and longevity.

Frequently Asked Questions

What Are the Typical Implementation Costs for Mixed Reality in Industrial Maintenance?

You’ll typically spend $50,000-$500,000 for mixed reality implementation, depending on your facility’s size and complexity. Hardware costs $2,000-$5,000 per device, while software development and training add significant expenses to your budget.

How Long Does It Take to Train Technicians on Mixed Reality Systems?

You’ll typically need 2-4 weeks to train technicians on mixed reality systems. Basic navigation takes a few days, while mastering complex maintenance procedures requires additional practice. Your team’s tech experience greatly affects learning speed.

Which Mixed Reality Headsets Work Best in Harsh Industrial Environments?

You’ll want ruggedized headsets like Microsoft HoloLens 2 Industrial Edition or Magic Leap 2 with protective casings. They’re built to withstand dust, moisture, and temperature extremes that’d destroy consumer-grade devices.

How Do You Measure ROI From Mixed Reality Maintenance Investments?

You’ll measure ROI by tracking reduced downtime, faster repair times, lower training costs, and decreased travel expenses. Compare these savings against your initial hardware investment and ongoing software costs to calculate your return percentage.

What Internet Connectivity Requirements Are Needed for Mixed Reality Maintenance Tools?

You’ll need stable broadband with at least 25 Mbps download speeds for cloud-based processing. Consider 5G or dedicated WiFi 6 networks for lower latency. Backup connectivity options guarantee you won’t lose critical maintenance data during operations.

Leave a Reply