You’ll revolutionize your automotive design process with mixed reality’s immersive 3D visualization capabilities that let you examine full-scale vehicle models from every angle while identifying design issues early. You can collaborate with global teams in shared virtual spaces, make real-time adjustments without expensive physical prototypes, and reduce costs by up to 90% in early design phases. Mixed reality accelerates your timeline from concept to market while enhancing customer engagement through interactive experiences that transform how you develop and showcase vehicles.

Enhanced 3D Design Visualization Capabilities

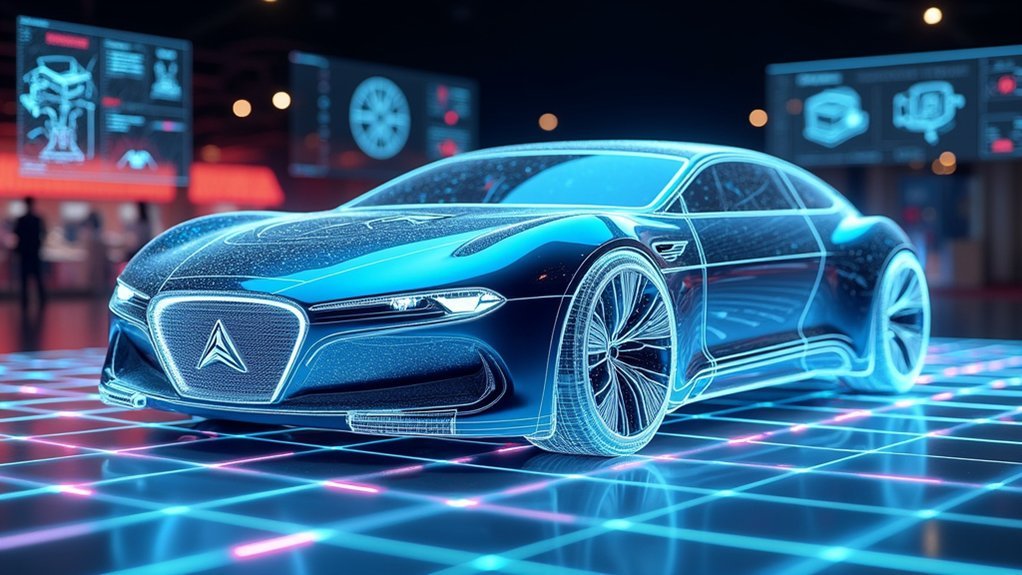

While traditional automotive design has long relied on flat sketches and computer screens, mixed reality transforms how you visualize vehicle concepts by immersing you directly within three-dimensional space.

With MR technology, you’ll experience car models at full scale, walking around them to examine every angle and detail with unprecedented clarity.

Mixed reality lets designers walk around full-scale car models, examining every detail with unprecedented three-dimensional clarity.

This immersive approach gives you an intuitive understanding of proportions and aesthetics that’s impossible to achieve through traditional 2D methods. You can instantly assess how design elements work together, spotting potential issues before they become costly problems.

The spatial awareness that mixed reality provides helps you make more informed decisions about styling, ergonomics, and overall vehicle appeal, fundamentally changing your design process.

Real-Time Collaborative Design Reviews

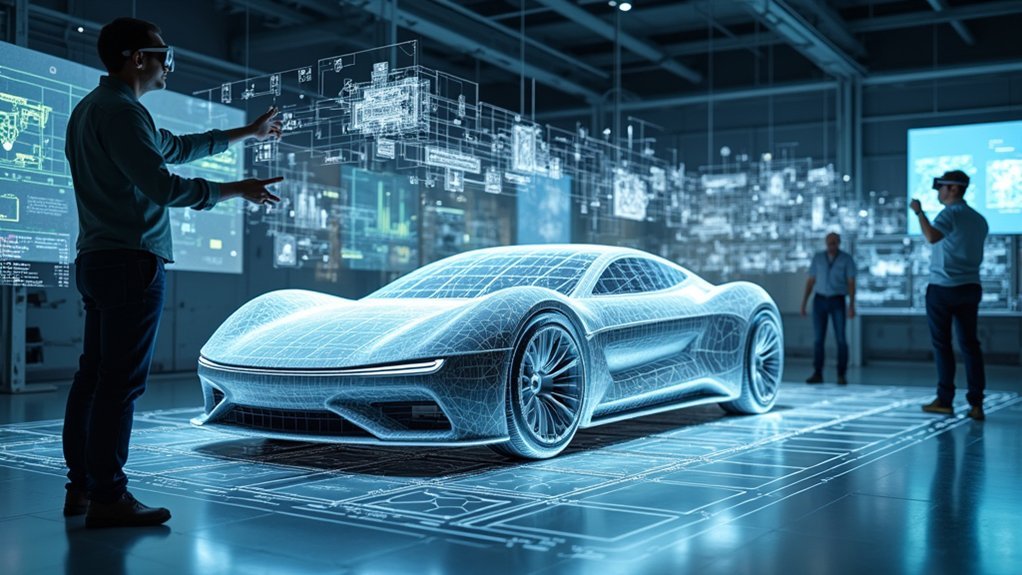

When design teams are scattered across continents, mixed reality bridges the geographical divide by creating shared virtual spaces where you can collaborate on vehicle designs as if you’re standing in the same room.

You’ll interact with 3D car models simultaneously, making instant adjustments to aesthetics and features during virtual meetings. This seamless blend of real and virtual worlds transforms automotive design reviews from lengthy, fragmented processes into dynamic collaborative sessions.

High-resolution experiences foster trust and engagement among stakeholders, while the immersive nature lets you explore designs from multiple angles.

You’ll gather deeper feedback and accelerate decision-making, shortening review phases from months to weeks. Mixed reality eliminates costly physical prototypes while maintaining the quality of traditional automotive design collaboration.

Streamlined Prototyping and Development Processes

You’ll accelerate your design iterations dramatically when mixed reality enables your team to test multiple concepts simultaneously in virtual environments.

This technology reduces your dependency on expensive physical prototypes during early development phases, cutting costs and minimizing material waste.

You can make real-time adjustments to design elements while maintaining seamless integration with your existing CAD workflows.

Faster Design Iterations

As automotive designers embrace mixed reality technology, they’re discovering unprecedented speed in their design iteration cycles.

You’ll find that mixed reality tools enable real-time visualization and manipulation of 3D car models, dramatically cutting prototyping time. Instead of waiting months for physical prototypes, you can create virtual versions of vehicles that allow immediate testing of multiple design features simultaneously.

The integration with existing CAD software streamlines your workflow, making team collaboration seamless without requiring physical models.

You’ll receive instant feedback on design changes, accelerating development and shortening design phases from months to weeks. Enhanced visualization capabilities help you identify potential flaws early, minimizing costly revisions.

This efficiency guarantees faster design iterations while maintaining quality standards throughout your development process.

Reduced Physical Prototypes

While traditional automotive development relies heavily on expensive physical prototypes, mixed reality technology transforms this approach by enabling you to create thorough virtual models that eliminate the need for multiple costly iterations.

You can visualize complete vehicle designs in 3D space, testing components and systems without manufacturing physical mockups. This shift dramatically reduces material costs and manufacturing expenses typically associated with prototype development.

Mixed reality allows you to validate design concepts early in the development phase, catching potential issues before committing resources to physical construction.

You’ll experience faster decision-making processes as stakeholders can interact with virtual prototypes immediately. The technology enables simultaneous testing of multiple design variations, helping you optimize features without producing numerous physical versions.

This streamlined approach accelerates your overall development timeline while maintaining design quality.

Cost Reduction Through Virtual Testing

Innovation in mixed reality transforms automotive development by slashing the enormous expenses tied to traditional prototyping methods. Virtual testing eliminates the need for multiple physical models while reducing cost and waste throughout your development cycle.

| Testing Phase | Traditional Cost | MR Virtual Cost | Savings |

|---|---|---|---|

| Early Design | $500,000 | $50,000 | 90% |

| Performance Testing | $750,000 | $75,000 | 90% |

| Safety Validation | $300,000 | $45,000 | 85% |

| Feature Integration | $400,000 | $40,000 | 90% |

| Final Validation | $200,000 | $30,000 | 85% |

You’ll achieve dramatic cost reductions by simulating performance scenarios without physical testing expenses. MR enables simultaneous testing of multiple design features, preventing costly rework from late-stage changes. Your teams can iterate quickly, making decisions faster while maintaining quality standards.

Immersive Customer Experience and Marketing

Revolutionary engagement awaits your customers through mixed reality’s immersive automotive experiences that transform how they discover and connect with vehicles.

You’ll captivate potential buyers by letting them interact with virtual car models in dynamic environments that make vehicle selection more engaging and informative.

MR solutions deliver breakthrough marketing opportunities that enhance customer relationships:

- Real-time feature demonstrations showcase vehicle capabilities and aesthetics before purchase decisions

- Social media AR integration creates bespoke brand experiences that deepen consumer connections

- Affordable smart glasses accessibility expands your reach to broader audiences seeking immersive experiences

Companies like BMW prove MR’s effectiveness through successful campaigns featuring vehicles like the Concept i4.

These immersive customer experience strategies increase brand awareness while giving customers thorough understanding of your vehicles’ value propositions.

Advanced Training and Simulation Environments

As automotive systems grow increasingly complex, mixed reality transforms how you train engineers and technicians by creating realistic simulation environments that replicate real-world scenarios without the costs and constraints of physical resources.

Advanced MR technology lets you experiment with new automotive technologies virtually, dramatically reducing expenses while maintaining training quality.

These interactive training environments boost knowledge retention and skill development, resulting in higher precision during assembly and operations.

You can simulate diverse driving conditions and vehicle interactions through MR, enabling thorough performance testing before building physical prototypes.

This innovative approach helps you address skilled technician shortages while improving operational efficiency.

Seamless Integration With Existing CAD Workflows

While traditional CAD workflows have served the automotive industry well, mixed reality technology now bridges the gap between digital design and physical visualization without disrupting your established processes.

You can integrate MR tools directly with your existing CAD software, maintaining productivity while enhancing visualization capabilities.

MR transforms your design phase by enabling:

- Real-time collaboration where teams manipulate 3D models together, providing immediate feedback and reducing iteration cycles

- Immersive prototype interaction that lets stakeholders experience virtual designs before physical production, optimizing elements early

- Cost-effective development by minimizing expensive physical prototypes during initial design stages

Your familiar design environment remains intact while mixed reality enhances your team’s ability to visualize, collaborate, and refine automotive designs more efficiently than ever before.

Accelerated Decision-Making Through Instant Feedback

When design iterations that once took days or weeks can now happen in minutes, mixed reality fundamentally transforms how automotive teams make critical development decisions.

Mixed reality accelerates automotive design iterations from weeks to minutes, revolutionizing how development teams make crucial decisions.

You’ll receive instant feedback on every design change, eliminating the traditional delays that slow down vehicle design processes. Rather than waiting for physical prototypes or lengthy rendering cycles, you can visualize modifications immediately in 3D space and assess their impact on the spot.

This real-time feedback loop enables your team to evaluate multiple design concepts rapidly, comparing alternatives and making informed choices without interrupting workflow momentum.

You’ll identify potential issues early, adjust proportions instantly, and validate aesthetic decisions before committing resources to physical production. The result is streamlined decision-making that keeps your automotive projects moving forward efficiently.

Cross-Platform Compatibility and Accessibility

The speed of these instant design decisions becomes even more powerful when your entire team can participate regardless of their device preferences or technical setup.

Cross-platform compatibility guarantees that engineers using Windows workstations, designers on MacBooks, and stakeholders with mobile devices can all access the same virtual prototypes seamlessly.

Your MR tools integrate directly with existing CAD software, eliminating workflow disruptions and maintaining design integrity across platforms.

This accessibility empowers diverse team members—from engineers to marketing professionals—to contribute meaningful feedback using affordable MR wearables.

Key benefits include:

- Real-time collaboration among global teams without geographical limitations

- Seamless shifts between different platforms and operating systems

- Enhanced engagement through diverse interactive experiences that leverage various MR technologies

Manufacturing Assembly Assistance and Quality Control

As your automotive prototypes shift from virtual design to physical production, mixed reality transforms how assembly teams execute complex manufacturing tasks with pinpoint accuracy.

You’ll equip technicians with real-time heads-up displays that overlay 3D assembly instructions directly onto physical components, greatly reducing errors and accelerating production timelines.

Your quality control processes become more rigorous when inspectors can overlay digital checklists onto actual parts, ensuring every specification meets standards before final assembly.

You’ll cut training costs remarkably as workers visualize complex procedures in three-dimensional space, making intricate tasks immediately comprehensible.

Remote troubleshooting capabilities let your experts guide on-site teams globally without physical presence.

This manufacturing assembly assistance creates seamless communication channels where team members share insights within shared virtual environments, streamlining workflows across your entire automotive production operation.

Future-Ready Technology for Automotive Innovation

While traditional automotive development cycles once stretched across years, mixed reality now accelerates your innovation timeline from concept to market in ways previously unimaginable.

You’re witnessing a fundamental shift as major automotive brands embrace MR technologies to transform their operations. This future-ready approach positions your company at the forefront of industry evolution, where immersive visualization replaces outdated development methods.

Key advantages of adopting MR for automotive innovation include:

- Streamlined workflows that integrate seamlessly with existing CAD software for enhanced global collaboration

- Cost-effective training environments that simulate complex vehicle systems without physical resources

- Enhanced customer experiences through interactive demonstrations and personalized vehicle configurations

As the automotive landscape evolves, mixed reality isn’t just an option—it’s becoming essential for maintaining competitive advantage and meeting tomorrow’s market demands.

Frequently Asked Questions

How Is VR Used in the Automotive Industry?

You’ll find VR transforms automotive design through immersive 3D reviews, realistic driving simulations, technician training, and collaborative brainstorming. It accelerates development timelines while reducing costs before creating physical prototypes.

Why Is Recognizing Mixed Reality as a Category of Extended Reality Important for Business Leaders?

You’ll understand MR’s strategic potential within XR’s broader ecosystem, enabling informed technology investments. This recognition helps you anticipate industry trends, leverage competitive advantages, and make data-driven decisions about emerging technologies.

How Is Augmented Reality Used in the Automotive Industry?

You’ll find augmented reality transforms automotive experiences through immersive marketing campaigns, AR navigation systems displaying real-time driving information, interactive virtual car models for customers, manufacturing repair assistance, and realistic training simulations for employees.

What Are the Characteristics of Mixed Reality?

You’ll experience seamless blending of digital and physical environments where you can interact with virtual objects as if they’re real. You’ll manipulate holograms, collaborate naturally, and perceive depth accurately in shared spaces.

Leave a Reply